Micro molding, as the name suggests, is smaller injection molding process. However, technically speaking, it is not just about smaller sizes. Due to the small size of the plastic molding product and mold, the dimensional tolerance will also decrease, which is difficult for ordinary mold factories to achieve.

With the increasing global demand for miniaturized and high-performance products, the application prospects of micro molding technology in the market are becoming increasingly broad. Whether in the communication technology, medical equipment, or automotive industries, micro injection molding technology can provide customized solutions to meet the market's demand for high-performance micro components.

We are proud to have successfully manufactured micro injection molds for our customers in the past, proving our ability in plastic injection molding. This indicates our commitment to providing the most agile manufacturing services for customers who require small precision plastic molds.

We have unique experience in the design and manufacturing of micro injection molds, and we have good relationships with suppliers of accessories required for micro injection molds, which can provide customers with cost discounts. For example, hot runners are commonly used in micro injection molds, which allow for more precise temperature control of multi cavity molds, improve part quality, and shorten cycle time.

The gate of micro molded components must be appropriately sized to avoid excessive thermal stress on the material entering the mold cavity. Most micro molded parts use edge gating, and we need to remove the gating appropriately to avoid small material issues causing arterial damage (in implanted devices) or automation and assembly problems. In mold design, these problems can be solved by placing a pit on the wall thickness, so that the gate residue will be designed below the surface of the guide rails or mating parts in the component.

The parting line of micro injection molds is related to the size of micro parts. A difference of 10 microns on the parting line can easily disrupt the assembly of the product.

The more the demolding slope of micro injection molded parts, the better, but the minimum taper can also be as small as 0.2 degrees. This kind of taper can be very troublesome to handle for injection molded parts. Placing micro components on a taper will create an irregular surface, which can affect assembly.

The selection of surface smoothness for mold parts is also very important. For example, some products require a rougher surface to achieve better adhesion. A too smooth surface may cause the product to stick to the mold cavity when ejected out, so micro injection mold designers need to consider a compromise.

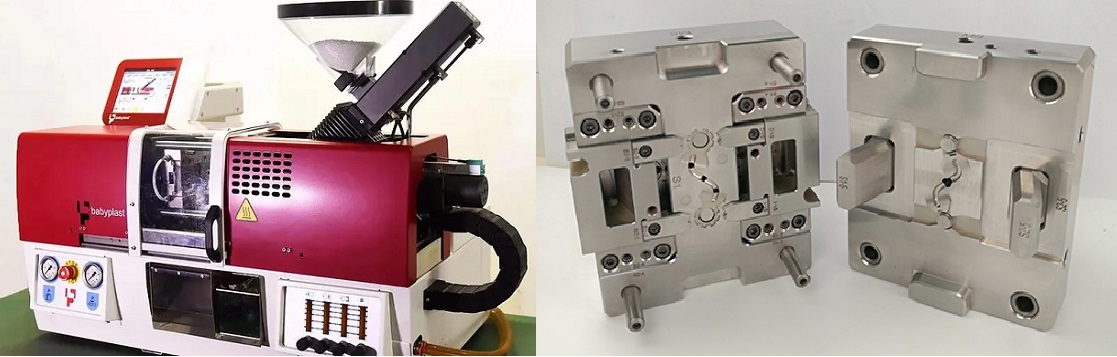

For mold trial, we use Babyplast machines, which are an ideal choice for centimeter to millimeter sized plastic parts.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.